Maximizing London’s Warehouses: 7 Ways to Optimize Space Utilization

In the heart of London’s bustling industrial landscape, where space is as precious as the city’s history, optimizing warehouse space utilization is a challenge businesses must conquer. With every square foot holding the potential for increased efficiency and cost savings, the quest to discover innovative solutions for warehouse management becomes paramount. In this exploration, we delve into the seven transformative strategies that can unlock the hidden potential within London’s warehouses, ensuring they not only stand the test of time but also thrive in the modern business environment.

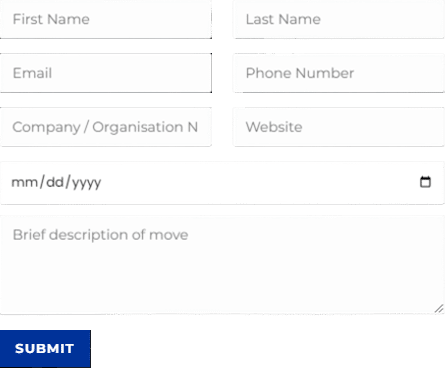

Discuss Your Move Today

Give us a call at 0208 575 1133, or use the form below to book your service.

This page supports our content about commercial storage solutions and you can find other in-depth information about What is the modern method of storage in London by following this link or answers to related questions like What are the three common storage technologies in London if you click here.

Before we delve into the details of optimizing warehouse space utilization in London, let’s address some frequently asked questions about commercial storage solutions to set the stage for efficient warehouse management.

What is 5S in warehouse in London?

5S in a warehouse, widely practiced in London and globally, is a structured system for organizing and maintaining a clutter-free, efficient workspace. It stands for Sort, Set in order, Shine, Standardize, and Sustain. Businesses invest in 5S initiatives, with costs typically ranging from hundreds to thousands of pounds, to streamline operations, improve safety, and optimize space utilization.

What are the five 5 main activities of a warehouse in London?

The five main activities of a warehouse in London, crucial for business inventory management, include:

The costs can vary based on the scale and complexity of the warehouse operations in London.

Receiving (£500-£2,000+): Receiving goods and inspecting them for quality and quantity upon arrival.

Storage (£1,000-£5,000+): Properly storing and organizing items, ensuring accessibility and security.

Picking and Packing (£2,000-£10,000+): Selecting items from storage and preparing them for shipment.

Shipping (£500-£2,000+): Packaging, labeling, and dispatching products to customers.

Inventory Control (£1,000-£5,000+): Tracking stock levels, managing reorder points, and optimizing inventory.

How do you manage a large warehouse in London?

Managing a large warehouse in London involves several key strategies:

Budgets vary based on warehouse size and requirements, ensuring smooth commercial storage solutions in London.

Advanced Storage Systems (£10,000-£100,000+): Invest in high-density racking, automated shelving, and mezzanine systems to maximize space.

Inventory Management Software (£5,000-£20,000+): Implement robust software for real-time tracking, order processing, and demand forecasting.

Labour and Training (£20,000-£50,000+): Employ skilled staff and provide ongoing training for efficient operations.

Security (£5,000-£20,000+): Enhance security with CCTV, access control, and inventory tracking systems.

Regular Audits (£5,000-£10,000+): Conduct routine audits to maintain accuracy and compliance.

How can I make my warehousing better in London?

To enhance your warehousing in London, consider these steps:

Budgets vary based on warehouse size and specific industrial asset reserve systems requirements.

Optimise Layout (£2,000-£10,000+): Reconfigure your space for efficient flow and accessibility.

Implement Asset Tracking (£5,000-£20,000+): Invest in asset tracking systems to monitor inventory and assets.

Upgrade Security (£1,000-£5,000+): Enhance security measures, including surveillance and access control.

Utilise Technology (£5,000-£20,000+): Embrace automation, RFID, and inventory management software.

Staff Training (£2,000-£5,000+): Train employees for improved efficiency and safety.

What are 3 goals in maintaining a modern warehouse in London?

Maintaining a modern warehouse in London, especially for a for-profit organization utilizing self-storage systems, typically involves these three goals:

Budgets vary based on warehouse size and specific self-storage system requirements.

Efficiency (£10,000-£50,000+): Streamline operations to optimize resource use and reduce costs.

Security (£5,000-£20,000+): Invest in advanced security measures to protect stored assets and meet compliance standards.

Customer Satisfaction (£2,000-£10,000+): Provide excellent service, ensuring client needs are met and contracts are renewed.

How do you manage warehouse utilization in London?

Effectively managing warehouse utilization in London involves these key steps:

Budgets vary depending on the warehouse size and specific industrial asset reserve system requirements.

Optimize Layout (£5,000-£20,000+): Rearrange storage space for efficient flow and accessibility.

Implement Asset Tracking (£10,000-£50,000+): Invest in asset tracking systems for real-time inventory monitoring.

Enhance Security (£2,000-£10,000+): Upgrade security with CCTV, access control, and inventory tracking.

Utilize Technology (£20,000-£100,000+): Embrace automation, RFID, and advanced inventory management software.

Employee Training (£5,000-£20,000+): Train staff for improved efficiency and safety.

What are the 6 steps of warehousing in London?

The six steps of warehousing, particularly for a for-profit organization using self-storage systems in London, include:

Receiving (£5,000-£20,000+): Receiving and inspecting goods upon arrival.

Storage (£10,000-£50,000+): Properly storing items for easy access and security.

Inventory Management (£2,000-£10,000+): Implementing inventory tracking systems for accurate records.

Picking and Packing (£5,000-£20,000+): Selecting and preparing items for shipment.

What is space optimization in London?

Space optimization in London, within the context of commercial storage solutions, refers to the efficient use of available storage areas to maximize functionality, accessibility, and cost-effectiveness. Businesses typically invest thousands to tens of thousands of pounds in various strategies, such as advanced shelving systems, high-density racks, and intelligent layout design, to make the most of their storage space while ensuring it meets their specific needs and objectives.

How can we reduce warehouse waste in London?

Reducing warehouse waste in London involves several key steps:

Budgets vary depending on warehouse size and the specific waste reduction measures implemented.

Optimise Inventory (£5,000-£20,000+): Implement efficient inventory management to minimize overstock and obsolescence.

Recycle and Reuse (£2,000-£10,000+): Establish recycling programs and reuse materials where possible to reduce waste.

Lean Practices (£10,000-£50,000+): Adopt lean principles to eliminate unnecessary processes and reduce excess inventory.

Energy Efficiency (£5,000-£20,000+): Invest in energy-efficient lighting and HVAC systems to reduce utility costs and environmental impact.

Employee Training (£2,000-£10,000+): Train staff to follow waste reduction practices.

In

Ready to transform your warehouse into a space-efficient powerhouse? Contact Universal Commercial Relocation today at 0208 575 1133, and let us help you unlock the potential of your London warehouse. Your efficient and cost-effective solutions are just a call away!